Home > Industries > Contract Manufacturing

Contract manufacturing offers a number of benefits:

Companies save on their capital costs because they do not have to pay for a facility and the equipment needed for production. They can also save on labor costs such as wages, training, and benefits. Some companies may look to contract manufacture in low-cost countries, such as China, to benefit from the low cost of labor.

A contract between the manufacturer and the company it is producing for may last several years. The manufacturer will know that it will have a steady flow of business at least until that contract expires.

Companies can take advantage of skills that they may not possess, but the contract manufacturer does. The contract manufacturer is likely to have relationships formed with raw material suppliers or methods ofefficiency within their production.

Contract Manufacturers are likely to have their own methods of quality control in place that help them to detect counterfeit or damaged materials early.

Companies can focus on their core competencies better if they can hand off base production to an outside company.

Contract Manufacturers have multiple customers that they produce for. Because they are servicing multiple customers, they can offer reduced costs in acquiring raw materials by benefiting from economies of scale. The more units there are in one shipment, the less expensive the price per unit will be.

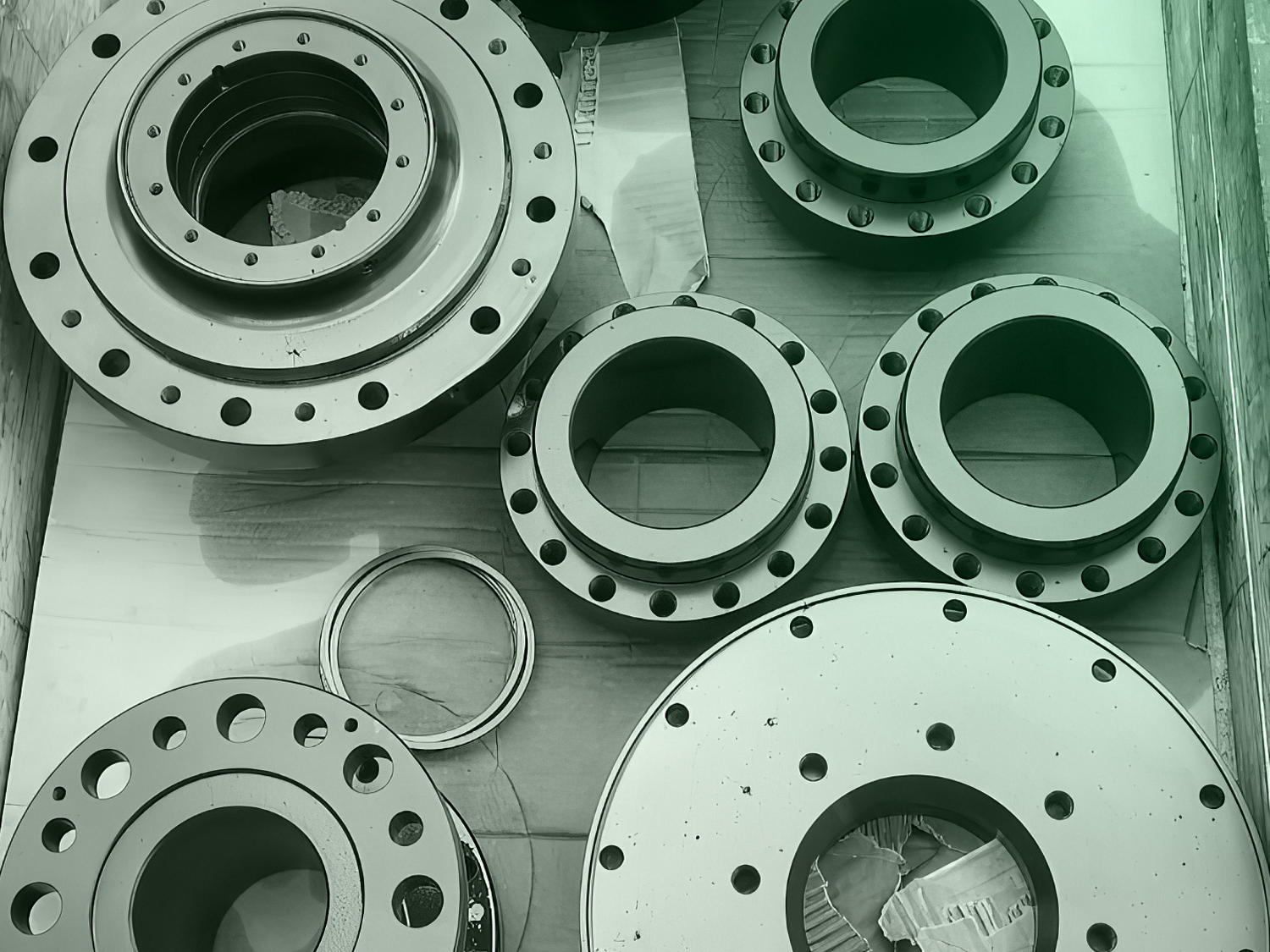

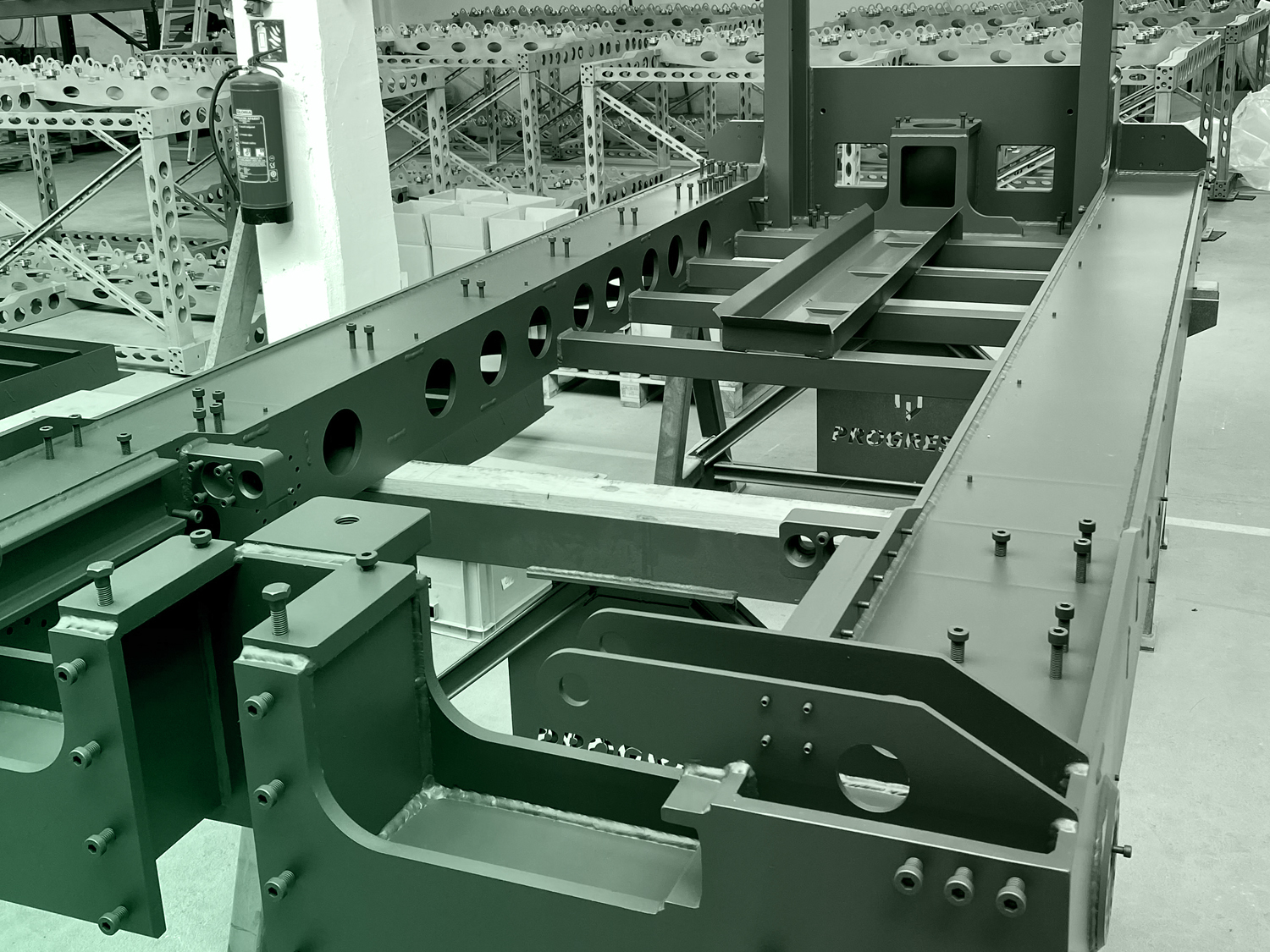

Progresys' range of services in the field of welded constructions is diverse and includes individual parts or complete assemblies or sophisticated machine components. The constructions are made of steel, stainless steel and aluminum.

In today's competition, quality is a decisive factor in all efforts to win customers' favor. Quality thinking is therefore an indispensable performance feature and plays the key role in our company. To optimize our company and thus trust To strengthen customers even more, Progresys M&E GmbH has all kinds of certificates that are specific to the mechanical engineering sector, with which a complete quality assurance is guaranteed. An environmentally friendly production based on the latest technology is also ensured.

Technologies

In today's competition, quality is a decisive factor in all efforts to win customers over.

Thermal coating technologies are versatile, which enables an almost unlimited number of coatings for a wide range of applications in engineering to protect components from high temperatures and oxidation. Coatings produced by thermal spraying become a practical option In order to be able to improve the wear and corrosion resistance and the thermal properties of a component. This also increases or decreases the friction or influences the electrical properties of the surface. Heat treatment distinguishes between methods that effect the processing of metallic materials as a whole, eliminating stresses and methods that only cause processing on the surface of a workpiece.

In cooperation with our process development department, we can also offer you machine-compatible solutions for demanding hardening tasks and inductive contract hardening in series. The required quality features are documented in our modern DIN ISO 9001 certified measuring and testing laboratory .

We can offer you the following hardening processes:

Glow

Hardening